Key Takeaways

- Digital twins boost supply chain agility and efficiency

- Industry leaders see improved efficiency and cost reduction

- Implementation needs clear goals and data integration

- Accurate location data ensures reliable digital twins

Introduction

Supply chain digital twins offer an innovative approach to supply chain management. They create virtual models of physical supply chains, allowing real-time data analysis, informed decision-making, and improved agility and efficiency.

What are supply chain digital twins exactly? And how can they enhance your supply chain operations? This article looks at the advantages of supply chain digital twins and shares practical examples of their implementation.

💡 Use accurate location data to build a supply chain digital twin. Our worldwide location data is updated weekly, relying on over 1,500 sources. Browse Geopostcodes datasets and download a free sample here.

What Is A Supply Chain Digital Twin?

A supply chain digital twin is not merely a digital double of the physical supply chain. It’s a sophisticated virtual model that leverages real-time data and advanced analytics to mirror and predict the behavior of the actual supply chain.

This dynamic, interactive tool goes beyond a simple 3D visualization; it learns from data, communicates with other digital entities, and aids decision-making processes.

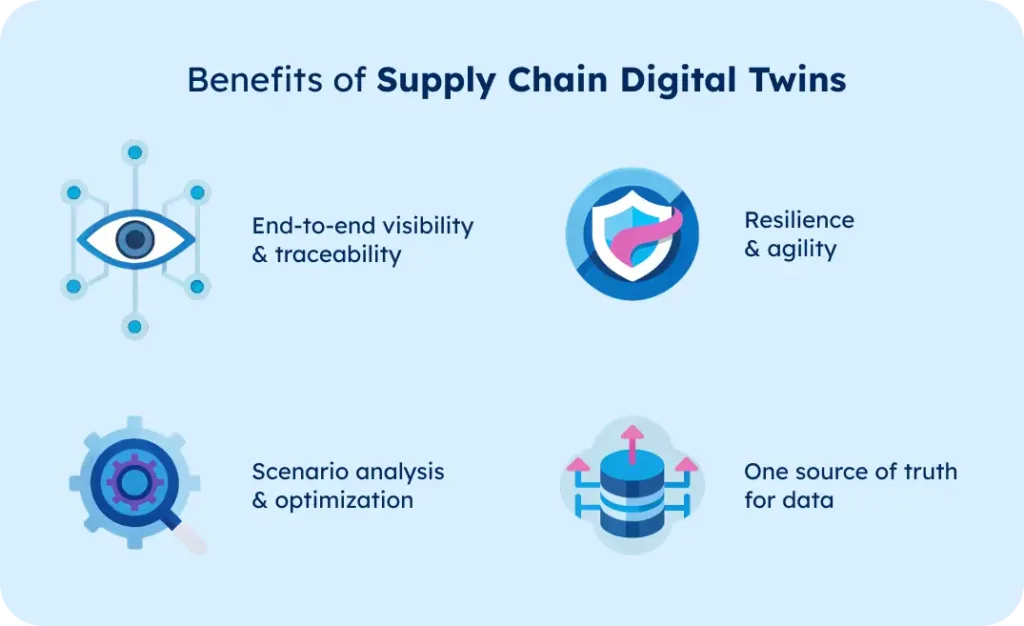

Benefits of Supply Chain Digital Twins

Implementing supply chain digital twins brings several advantages to the table, enhancing overall supply chain management:

- End-to-end visibility and traceability: By offering a bird’s-eye view of the entire supply chain, from the initial supplier to the final customer, digital twins facilitate monitoring of performance and status. They enable tracking of products and materials’ origins and destinations, strengthening transparency, quality, and compliance while minimizing waste and fraud.

- Scenario analysis and optimization: Digital twins empower supply chain professionals to simulate and evaluate scenarios and hypothetical questions, such as shifts in demand, supplier issues, transport delays, or environmental effects. This capability supports identifying the most efficient supply chain configuration and strategy, balancing profitability, risk, and sustainability.

- Resilience and agility: In today’s volatile market, digital twins allow supply chain entities to foresee and adapt to unforeseen disruptions, including pandemics, natural disasters, or geopolitical conflicts. Digital twins can mitigate risks, reduce expenses, and elevate customer satisfaction using real-time data and predictive analytics.

- One source of truth for data: By connecting all your data sources to your digital twin, you give every team contributing to your supply chain performance the same data to run, monitor, and plan their operations end-to-end.

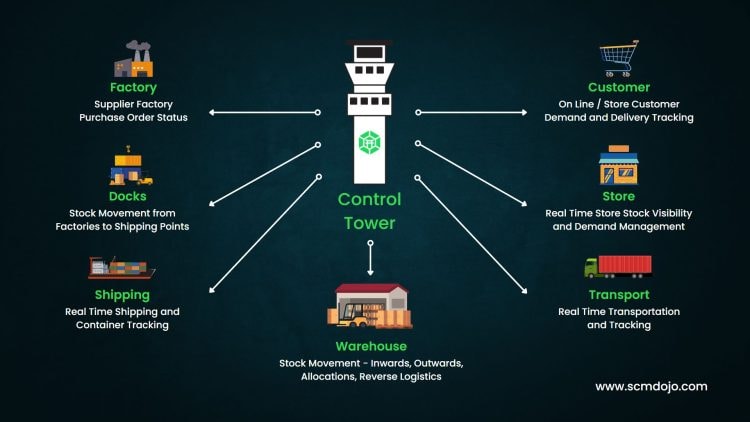

The difference between a digital twin and a control tower

The key difference between supply chain digital twins and supply chain control towers lies in their focus and functionality. A supply chain digital twin is a dynamic, real-time digital replica of the physical supply chain. It uses data from IoT devices, sensors, and other sources to simulate supply chain processes, predict outcomes, and optimize performance by enabling scenario analysis.

On the other hand, a supply chain control tower is a centralized hub that provides end-to-end visibility across the entire supply chain. It integrates data from multiple sources to offer insights and facilitate decision-making by monitoring operations, identifying disruptions, and coordinating responses. While digital twins are more about simulation and optimization, control towers focus on visibility and orchestration.

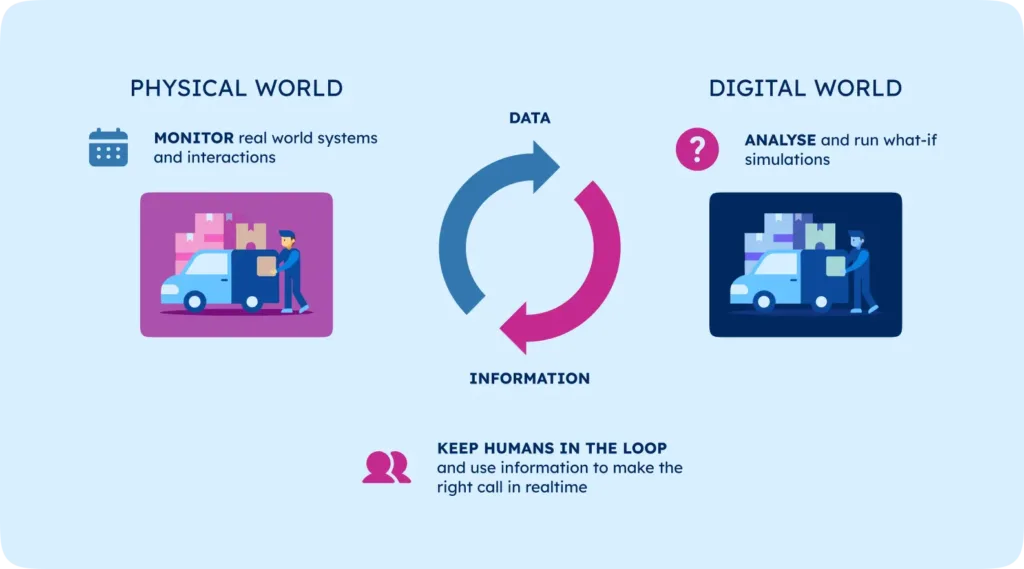

How Supply Chain Digital Twins Drive Agility and Efficiency

Boost Operational Agility and enable strategic planning

Supply chain digital twins empower organizations to swiftly respond to changing market dynamics, evolving customer needs, and unforeseen disruptions. By leveraging real-time data and sophisticated analytics, they offer valuable insights and guidance, enabling supply chain professionals to make more informed and timely decisions.

For instance, digital twins can optimize inventory management, transportation paths, production planning, and sourcing tactics in alignment with current and forecasted supply and demand. They also facilitate the assessment of various scenarios and options, like altering suppliers, modifying the product lineup, or introducing new offerings.

Enhance Supply Chain Efficiency

Furthermore, digital twins contribute to heightened operational efficiency and cost reduction. These digital tools pinpoint and rectify inefficiencies, bottlenecks, and redundancies by generating a comprehensive and precise supply chain representation. For example, they can monitor and fine-tune energy usage, resource allocation, and the environmental footprint of supply chain operations.

Additionally, they can identify and mitigate quality concerns, defects, and failures before they impact customers or final products. It strengthens the supply chain’s reliability, sustainability, and competitive edge.

Real-World Examples and Implementation Strategies

Cisco’s Service Supply Chain Digital Twin

Cisco is a multinational technology company that designs, manufactures, and sells networking hardware, software, telecommunications equipment, and other high-technology services and products. It is best known for its networking products, including routers, switches, and wireless systems.

Cisco’s critical mission is serving millions of customers in more than 130 countries. Since its hardware forms the backbone of the enterprise network and differentiates itself through exceptional customer service, it needs to offer a rapid response time—often less than 2 hours—to service its hardware when it stops working. To do so, it has more than 1,300 warehouses, thousands of engineers provided by global and local vendors, and hundreds of thousands of spare parts.

They moved from a spreadsheet-based system to a digital twin powered by a Geographical Information System, in this case, ArcGIS.

Driven by business rules and GIS location data, the digital twin delivers near-real-time insights, helping to deploy spare parts and technicians from the best warehouse and engineering base.

They managed to get several benefits from their new platform:

- Reduce unnecessary inventory

- Phase out redundant depots

- Add new depots to fill service gaps

- Improved drive-time accuracy by integrating real-time traffic and weather information

Location intelligence plays a key role in the accuracy of the digital twin. To achieve a reliable outcome at a global scale, they use Esri ArcGIS as a platform and reliable global location data as its foundation.

Walmart’s retail and supply chain digital twin

The well-known retailer Walmart uses digital twin technology to improve consumer experiences and increase operational efficiency. They experiment with various layouts and designs to maximize their retail layout. They can evaluate elements like product positioning and aisle design in the store.

Additionally, their inventory management system takes advantage of the technology. Companies first build a digital twin of their physical stores and stock it with virtual goods. Then, they evaluate and improve the stock levels, product positioning, and replenishment plans.

Lastly, they can also evaluate the effects of changes in demand, seasonal variations, or supply chain disruptions on inventory management by simulating various scenarios.

iFACTORY: BMW’s factory digital twin

BMW developed a digital twin of its factory to the nearest millimeter, enabling precise monitoring and optimization of production processes. This technology has minimized errors, enhanced quality, and boosted efficiency. It also facilitates the simulation of new products and processes before real-world implementation.

All production sites have been fully captured in a 3D scan – this creates a digital twin that you can virtually walk through in any location at any time, in real time, across different locations and time zones. It can, for example, realistically recreate a production line with machines and people. Employees can immerse themselves in the workplace by wearing virtual reality glasses and capturing and improving them digitally. It also enables new vehicles to be integrated into existing production lines – one example being the new all-electric BMW iX1. The result: It becomes apparent where action is still needed in the production chain. It saves significant time and effort.

BMW Group is taking a digital-first approach to validating and optimizing complex manufacturing systems across its production network. It uses NVIDIA Omniverse Enterprise, a platform for building and operating 3D industrial metaverse applications, to run real-time digital twin simulations to optimize layouts, robotics, and logistic systems virtually. Omniverse will be extended across the BMW product network around the world.

“Virtualisation and artificial intelligence are accelerating and refining our planning. With the various planning systems consolidated within a digital twin, our teams worldwide can work together in real-time and make decisions faster and on a more solid foundation,” Milan Nedeljković explained. “This makes us much quicker and more efficient and saves on costs.”

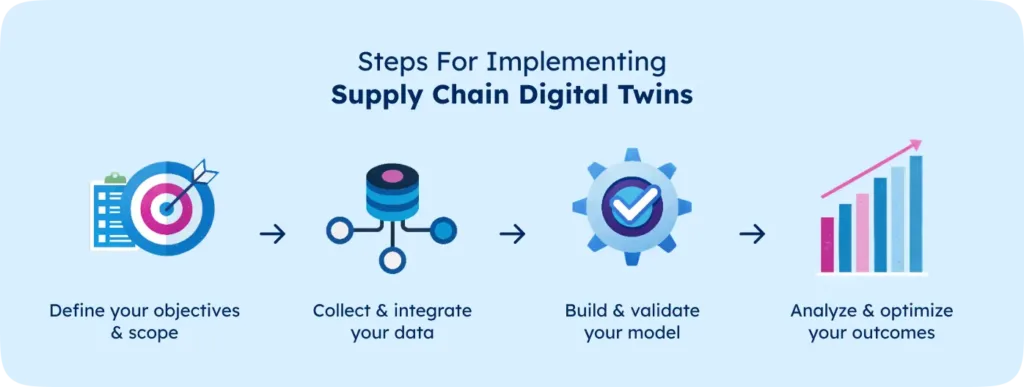

Implementing Supply Chain Digital Twins in Your Business

To integrate supply chain digital twins into your business, consider the following steps:

- Define your objectives and scope: Identify the challenges and opportunities you wish to address. Determine the key performance indicators you want to improve and outline the boundaries and components of your supply chain for modeling.

- Collect and integrate your data: Determine the necessary data sources and types. Ensure this data’s quality, accuracy, and timeliness and integrate it across various systems and platforms.

- Build and validate your model: Choose the appropriate tools and methods to create your supply chain digital twin. Ensure the model is realistic, reliable, and scalable, and validate it against real-world data and scenarios.

- Analyze and optimize your outcomes: Use your supply chain digital twin to derive insights and recommendations. Evaluate the impact and trade-offs of different scenarios and alternatives, and implement and monitor changes based on your digital twin’s findings.

Supply chain digital twins offer a tailored and versatile solution to meet business goals and needs. By adhering to these steps, you can develop and utilize a supply chain digital twin that aligns with your business context and challenges.

Tools to create your supply chain digital twin

Creating a supply chain digital twin involves using various tools and methods to ensure it’s comprehensive and accurate. Let’s explore some of the tools you can use.

Data Integration Platforms

Data integration platforms like Apache Kafka, Talend, and MuleSoft help seamlessly gather data from IoT devices, ERP systems, and other sources. These platforms ensure that your digital twin can access real-time, accurate data, which is crucial for simulation and analysis.

Maintaining data consistency and standardization during integration, especially for location data, is essential to achieving seamless data integration and avoiding duplicates or misalignment. This will form the core of your supply chain digital twin. That’s where providers of accurate and up-to-date data, such as GeoPostcodes, can help.

IoT Devices and Sensors

Internet of Things (IoT) devices and sensors are critical in providing real-time data to your digital twin. By deploying IoT devices across your supply chain, you can collect detailed data on various parameters such as temperature, humidity, location, and movement of goods. This data feeds into your digital twin, enabling real-time monitoring and predictive analytics. For example, IoT data can improve inventory management by providing visibility into stock levels and enabling proactive maintenance by predicting equipment failures before they occur.

Advanced Analytics and AI

Advanced analytics and artificial intelligence (AI) are crucial in turning raw data into actionable insights. Tools like SAS, IBM Watson, and Microsoft Azure AI offer robust analytics capabilities to process vast amounts of data, identify patterns, and predict potential disruptions. AI-driven algorithms can optimize supply chain operations by suggesting the best routes, inventory levels, and procurement strategies. Machine learning enhances predictive accuracy over time, continuously improving decision-making processes.

Simulation Software

Simulation software allows you to model different scenarios and predict their outcomes. Tools such as AnyLogic, Simul8, and FlexSim enable you to create detailed simulations of your supply chain processes. These simulations help identify bottlenecks, test new strategies, and understand the impact of changes before implementing them in the real world. Validating simulations against real-world data ensures their accuracy and reliability.

Digital Twin Platforms

Dedicated digital twin platforms like NVIDIA Omniverse, Esri ArcGIS, GE Digital’s Predix, Siemens’ MindSphere, and PTC’s ThingWorx provide comprehensive solutions for building and managing digital twins. These platforms offer real-time data visualization, advanced analytics, and integration capabilities, making creating and maintaining an accurate digital representation of your supply chain easier. Successful implementations of these platforms in real-world scenarios demonstrate their value and effectiveness.

Cloud Computing

Cloud computing platforms such as Amazon Web Services (AWS), Microsoft Azure, and Google Cloud provide the infrastructure needed to store and process the large volumes of data generated by your digital twin. These platforms offer scalable resources, ensuring your digital twin can handle increasing data loads and computational demands. Data security and compliance with industry regulations when using cloud services are essential to protect sensitive information.

Conclusion

In summary, supply chain digital twins represent a transformative technology that significantly enhances agility and efficiency in supply chain management. By creating virtual models that leverage real-time data and advanced analytics, businesses can achieve comprehensive visibility, optimize operations, and proactively address disruptions.

Real-world examples from industry leaders like Cisco, Walmart, and BMW illustrate the substantial gains in efficiency, cost reduction, and customer satisfaction achievable through digital twin technology.

Implementing this approach involves setting objectives, data integration, model validation, and continuous optimization using advanced tools and platforms.

As supply chain landscapes become increasingly complex, adopting digital twins can provide a competitive edge, reduce costs, and enhance overall performance. To start your journey towards a more efficient and resilient supply chain, consider leveraging accurate and up-to-date location data from GeoPostcodes. This foundational data will ensure reliable and effective digital twin implementations, ultimately driving better decision-making and operational success. Ready to transform your supply chain? Contact us today.

FAQ

What is a digital twin of a supply chain?

A digital twin of a supply chain is a virtual replica of the entire supply chain, including its processes, assets, and data. It allows businesses to simulate, analyze, and optimize their real-time supply chain operations.

Can a supply chain digital twin make you twice as agile?

Yes, a supply chain digital twin can significantly enhance agility by enabling faster decision-making, predicting disruptions, and optimizing operations. While it may not double agility, it can dramatically improve responsiveness and efficiency.

What is the digital twin approach?

The digital twin approach involves creating a virtual model of a physical object, system, or process. This model mirrors its real-world counterpart in real time, allowing for monitoring, simulation, and performance optimization throughout its lifecycle.

What is an example of a digital twin?

An example of a digital twin is a virtual model of an aircraft engine used by manufacturers to monitor performance, predict maintenance needs, and optimize operation. This digital replica helps prevent failures and extend the engine’s life.

How can digital supply chain twins help manage supply chain risks?

Digital supply chain twins offer a dynamic, real-time representation of the supply chain network. This allows supply chain leaders to manage supply chain risks more effectively by simulating different scenarios, identifying potential disruptions, and implementing proactive measures to mitigate those risks.

Why are supply chain leaders focusing on forecasting supply chain dynamics?

Supply chain leaders prioritize forecasting supply chain dynamics to anticipate changes and challenges within the network. By leveraging digital supply chain twins, they can predict fluctuations, optimize inventory levels, and ensure a resilient and agile supply chain.

What role do warehouse management systems play in digital supply chain twins?

Warehouse management systems are integral to digital supply chain twins, providing real-time data and control over warehouse operations. This integration enhances the accuracy and efficiency of the overall supply chain network, ensuring that inventory is managed effectively and supply chain dynamics are smoothly aligned.

How do digital supply chain twins enhance supply chain network visibility?

Digital supply chain twins offer a comprehensive view of the entire supply chain network, enabling supply chain leaders to monitor and optimize every aspect of the supply chain. This enhanced visibility allows for better decision-making, improved efficiency, and the ability to respond quickly to disruptions.

How can digital supply chain twins improve warehouse management systems?

By integrating warehouse management systems into digital supply chain twins, supply chain leaders can optimize warehouse operations, ensuring that inventory is aligned with real-time demand and forecast supply chain dynamics. This results in more efficient warehouse management and a more responsive supply chain network.