Introduction

Optimizing your existing supply chain network is a strategic process that tailors the network’s structure and configuration to meet your company’s strategic and operational goals. This process involves critical decisions about facility locations, transport paths, inventory levels, and sourcing tactics.

Why prioritize supply chain network design? The stakes are high, as it touches on cost, efficiency, service quality, and the overall sustainability of supply chain operations. A carefully crafted network can help reduce expenses, enhance customer satisfaction, manage risks effectively, and secure that all-important edge in the marketplace.

Let’s be clear, though: designing a robust supply chain network is a complex process. It demands extensive data, thorough analysis, detailed planning, and seamless coordination across various stakeholders. Moreover, it must account for the uncertainties, complexities, and evolving nature of today’s business landscape, such as moving prices of raw materials.

This blog is for people starting to get their hands on supply chain network design. Expect to learn about the foundational aspects, strategies to optimize your network, and the hurdles you will likely face. We’re also armed with practical tips and best practices to aid you in making better supply chain decisions for your existing network.

Understanding the Building Blocks of Supply Chain Network Design

Before jumping into strategies and potential challenges, let’s first dissect what supply chain network design involves and its primary components. Supply chain network design is about calibrating your company’s network to align with your strategic and operational objectives. This encompasses strategic facility placement, carefully selected transportation routes, well-calculated inventory levels, and thoughtful sourcing strategies.

Defining Supply Chain Network Design

Also known as network modeling, supply chain network design utilizes a mathematical framework to symbolize the network and its multiple facets. This model is instrumental in assessing various what-if scenarios, such as demand shifts, cost fluctuations, required service levels, and environmental considerations. It’s a tool to discover the most cost-effective and value-generating network setup for your organization and its clients.

Key Components of an Effective Network

A top-notch supply chain network comprises five core elements:

- Strategy: It’s about charting out your business’s aims, necessities, and expectations that directly influence the design of your supply chain. Strategy entails creating, managing, and optimizing business processes, performance targets, organizational structures, and tech infrastructures.

- Process: This piece of the puzzle involves the day-to-day operations and actions that bring the supply chain strategy to life. It encompasses how processes interact and the recommended practices to uphold.

- Model: This is a blueprint of the supply chain network, detailing elements such as facilities, product lines, transport assets, and material flows. It serves as a tool for analyzing and fine-tuning network throughput and functionality.

- Information: Information is the backbone of supply chain operations – it encompasses the data, insights, and intelligence that underpin planning, execution, monitoring, and decision-making. This component includes IT systems and tools that foster data exchange and transparency throughout the network.

- Performance: We discuss measuring and assessing the network’s outcomes against pre-set strategies and goals. Performance metrics, KPIs, and feedback systems are crucial for tracking progress and promoting continuous enhancement.

Role of Technology in Modern Network Designs

In the realm of contemporary supply chains, technology is a game-changer. It empowers supply chains to integrate, automate, and optimize various network components, delving into technologies that are remaking the landscape of supply chain network design.

- RFID: Radio-frequency Identification (RFID) is an advanced technology that employs radio waves for identifying and tracking various objects, including products, containers, and vehicles. RFID’s capabilities allow for real-time visibility and traceability within the supply chain, enhancing accuracy, security, and efficiency across the entire network.

- GS1 Global Standards: The GS1 organization, known globally, formulates and maintains a suite of standards for the reliable identification, capture, and sharing of information across supply chain networks. GS1 standards encompass items such as barcodes, electronic product codes (EPCs), and the global data synchronization network (GDSN), which promote interoperability and facilitate seamless collaboration among supply chain partners, ultimately improving network performance and product quality.

- Optimization Tools: These are sophisticated software applications that apply mathematical algorithms to find the most effective solutions for complex issues in network design, inventory management, and transportation planning, among others. By helping to reduce costs, enhance service levels, and boost sustainability, optimization tools are essential for advancing the efficacy of supply chain networks.

Strategies for Optimizing Your Supply Chain Network

With an understanding of the foundational elements of supply chain network design, it’s time to delve into strategies that can optimize your network to achieve your business objectives.

Below are three pivotal strategies to consider:

Adopting a Data-Driven Approach

Data is the cornerstone of supply chain design, supplying necessary information for network modeling and analysis. Embracing a data-driven approach means capitalizing on data to make informed, objective decisions. This includes gathering, cleansing, validating, and analyzing data from diverse sources such as historical transactions, market trends, and environmental conditions. Employing master data management tools is key to extracting insights for network design, enabling you to:

- Pinpoint the ideal number and locations of facilities to minimize costs and optimize service.

- Define the best product mix and logistics policies to harmonize demand and supply.

- Understand the implications of varying demands, costs, and risks to improve network effectiveness.

- Regularly update the network design to reflect changes and ensure alignment with your business objectives.

Emphasizing Flexibility and Scalability

Flexibility and scalability are vital in adapting to an ever-changing business landscape. A resilient network should be:

- Modular: Comprising facilities and transportation assets that can be swiftly reorganized or modified.

- Agile: Capable of rapidly addressing demand shifts or supply disruptions.

- Resilient: Able to recover from environmental shocks, ensuring operations can resume as usual.

- Innovative: Continually refining processes to meet evolving market demands and customer needs.

Integrating Sustainability and Ethics into Network Design

Considering environmental, social, and governance (ESG) criteria involves folding sustainability and ethics into network design, attending to the network’s broader impact. To integrate these principles:

- Minimize your carbon footprint through the use of sustainable energy and the optimization of transportation routes.

- Adhere to legal, ethical, and transparency standards, keeping clear ESG performance reports.

- Foster social responsibility by supporting local communities and advocating for diversity, equity, and fair labor practices.

- Ensure that network stakeholders benefit from high-quality products, customer satisfaction, and a strong corporate reputation.

Overcoming Common Challenges in Supply Chain Network Design

While designing a supply chain network is an ongoing endeavor that demands continuous refinement, supply chain managers often encounter challenges. Identifying and understanding these obstacles is crucial to developing strategies for overcoming them and ensuring the robustness of the network.

Addressing the Complexity of Global Networks

The advent of globalization has significantly increased the intricacy and unpredictability of supply chain networks. These networks now stretch across various countries, regions, and continents, entangled with different regulations, tariffs, taxes, currencies, cultures, and languages affecting network design decisions.

To tackle the complexity of these global networks, supply chain managers must:

- Carry out an exhaustive analysis of global market conditions, customer segments, and the competitive environment to discern the opportunities and challenges within network design.

- Implement advanced modeling and simulation tools to anticipate the impacts of different network design options and the necessary trade-offs, such as facility location, capacity, and configuration on network performance and costs.

- Engage in proactive collaboration and communication with network stakeholders, suppliers, customers, regulators, and partners to ensure network design goals and activities are well-aligned and coordinated.

Contingency Planning for Disruptions

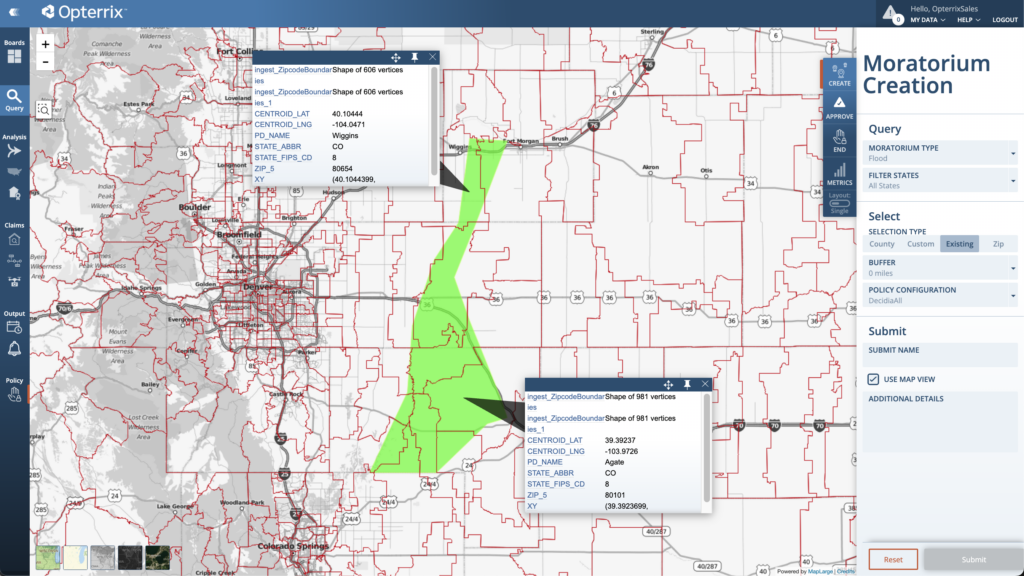

Supply chain networks are prone to disruptions—natural disasters, pandemics, cyberattacks, geopolitical conflicts, and demand shifts—all of which can lead to delays, shortages, and damage. Read how Geopostcodes helped Opterrix map natural hazard risk areas.

For effective contingency planning against these disruptions, supply chain managers must:

- Identify and evaluate potential disruption sources and their impact on the network using robust risk management practices that cover risk identification, analysis, evaluation, and mitigation.

- Create and implement contingency strategies, such as diversifying suppliers, arranging for backup facilities, establishing inventory safety nets, and assembling emergency response teams to mitigate the adverse effects of disruptions.

- Continually monitor and refine contingency strategies based on evolving circumstances and feedback to maintain the network’s resilience and ensure rapid recovery.

Cost vs. Service Level Considerations

In designing supply chain networks, managers face a fundamental trade-off between cost efficiencies and service levels, which define the quality and timeliness of products and services delivered to customers. Generally, enhancing service levels correlates with increased costs, and reducing costs can impact service levels.

To navigate cost and service level trade-offs, supply chain managers should:

- Understand customer requirements and expectations—product choice, availability, delivery promptness, and quality—to determine the most suitable service level for different customer segments.

- Refine network design elements such as the quantity and placement of facilities, transport networks, inventory volumes, and sourcing strategies to provide the desired service level as cost-effectively as possible.

- Track and enhance network performance through key performance indicators (KPIs), like total cost of ownership (TCO), customer satisfaction, and service level agreements (SLAs), ensuring that the network operates efficiently and effectively.

Conclusion

This is an introduction to supply chain network design, not a complete guide. Expertise in supply chain network design is essential for managers who aim to optimize their networks for strategic and operational success.

In this blog post, we’ve examined several crucial areas:

- The foundational elements of supply chain network design include strategy, processes, models, information, and performance metrics.

- Strategies for refining your supply chain network, like leveraging data-driven insights, prioritizing flexibility and scalability, and integrating sustainability and ethical practices.

- The typical hurdles in supply chain network design are managing the complexities of global networks, devising contingency plans for potential disruptions, and finding the right balance between costs and service levels.

Geopostcodes provides location data to create complex analyses like supply chain network design and allow you to understand, visualize, and take action on the insights derived from your analysis. Read how DB Schenker uses our zip code data to improve supply chain network design.

FAQ

What is network structure in supply chain?

The network structure in a supply chain defines the layout and connections among various entities involved in the production and distribution of goods or services. It outlines how suppliers, manufacturers, distributors, and customers are interlinked and collaborate to facilitate the flow of products, information, and finances. This structure can take different forms such as linear, hub-and-spoke, decentralized, or collaborative networks, each impacting factors like efficiency, responsiveness, and cost-effectiveness within the supply chain ecosystem.

What are the three levels of supply chain network design?

- Strategic Level: This focuses on long-term decisions concerning the overall supply chain structure, including facility locations, distribution centers, partnerships, and major investments. It aims to align the supply chain with the company’s objectives and market demands.

- Tactical Level: This level involves medium-term planning to optimize supply chain operations, encompassing decisions related to inventory management, transportation, supplier contracts, capacity planning, and supply chain personnel. It aims to balance cost and service level objectives while adapting to changing market conditions.

- Operational Level: This level pertains to day-to-day activities and execution within the supply chain. It involves routine decisions regarding production scheduling, order processing, inventory control, and logistics to ensure the efficient functioning of the supply chain based on the established strategic and tactical plans.

What are the key components in designing a supply chain network?

Key components in designing a global supply chain network model include facility layout and location planning, transportation strategy optimization, inventory management for efficient stock levels, robust information systems for data and process management, and strong supplier/partner relationships for reliability and collaboration. These components collectively aim to enhance efficiency, reduce costs, and improve responsiveness within the supply chain network.

What are the considerations for supply chain network design?

Considerations for supply chain network design involve customer-centric planning, cost optimization, flexibility for responsiveness, risk management strategies, and sustainability integration to meet environmental goals and regulations while enhancing operational efficiency.